Description

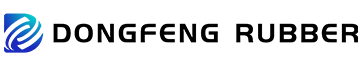

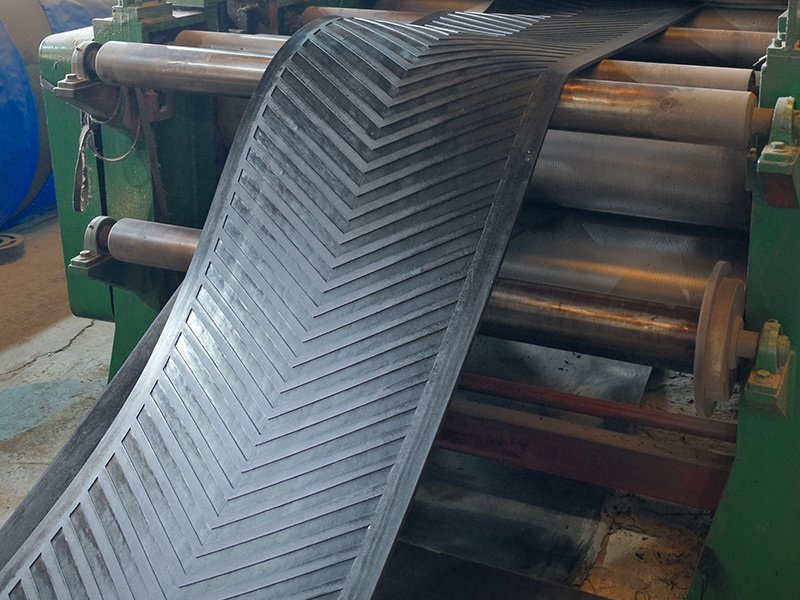

Conveyor roller are components of belt conveyor systems as they provide load support on carry side and return side.

The conveyor roller are standardised and designed according to ISO, DIN and EN standards. Custom made rollers are available on request. We have the capable of delivering a range of special-design rollers: water proof rollers, rollers for extreme climate conditions, conveyor roller for extreme loading, high speed conveyor rollers, low noise rollers, rollers for chemical conditions and case-hardened rollers.

Usage

Mining,Steel mill,Cement plant,Power plant,Chemical Plant,Sea Port,Storage,etc.

Characteristics

1. Low Total Indicator Run-out (T.I.R), low rotational resistance;

2. End cap to tube welds protected from rubber belt wear;

3. Highly-effective labyrinth seals protected from dust & water into the bearing;

4. Designed and manufactured for a long, trouble-free life;

5. Maintenance-free, high-quality sealed ball bearing.

Structure

Standard Specifications:

Roller Diameter: 89, 102, 108, 114, 127, 133, 140, 152, 159, 165, 178, 194, 219mm

Roller Length: 100-2400mm

Shaft Diameter: 20, 25, 30, 35, 40, 45, 50mm

Bearing type: 6204, 6205, 6305, 6206, 6306, 6307, 6308, 6309, 6310

Surface Treatment: Electrostatic Powder Coating, Galvanization

Standard: DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

Steel Conveyor Idler

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

Steel Conveyor Idler

Contact Us

Classification

Keywords