Usage

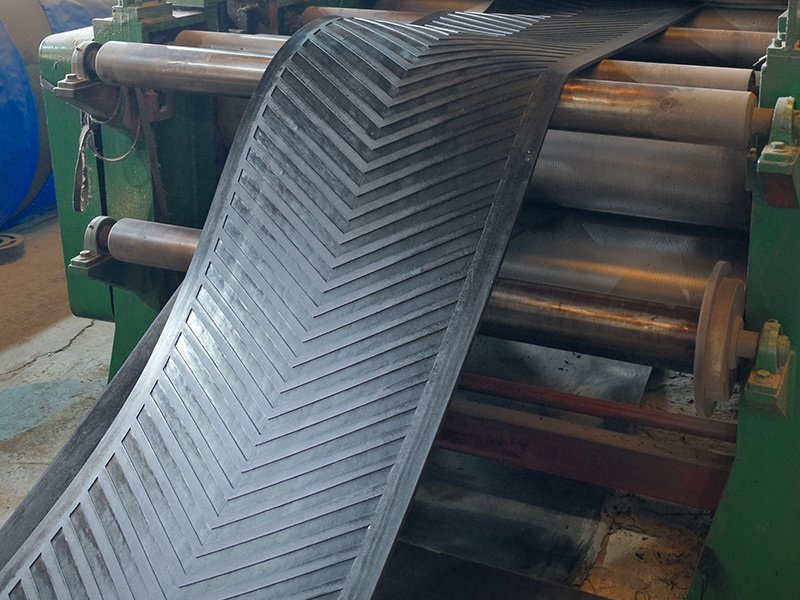

It’s suitable for transportation of hard and sharp materials in larger drop height occasions, used in lines of mines, ports, electricity, metallurgy, chemical industry, coalmines, etc.

Characteristics

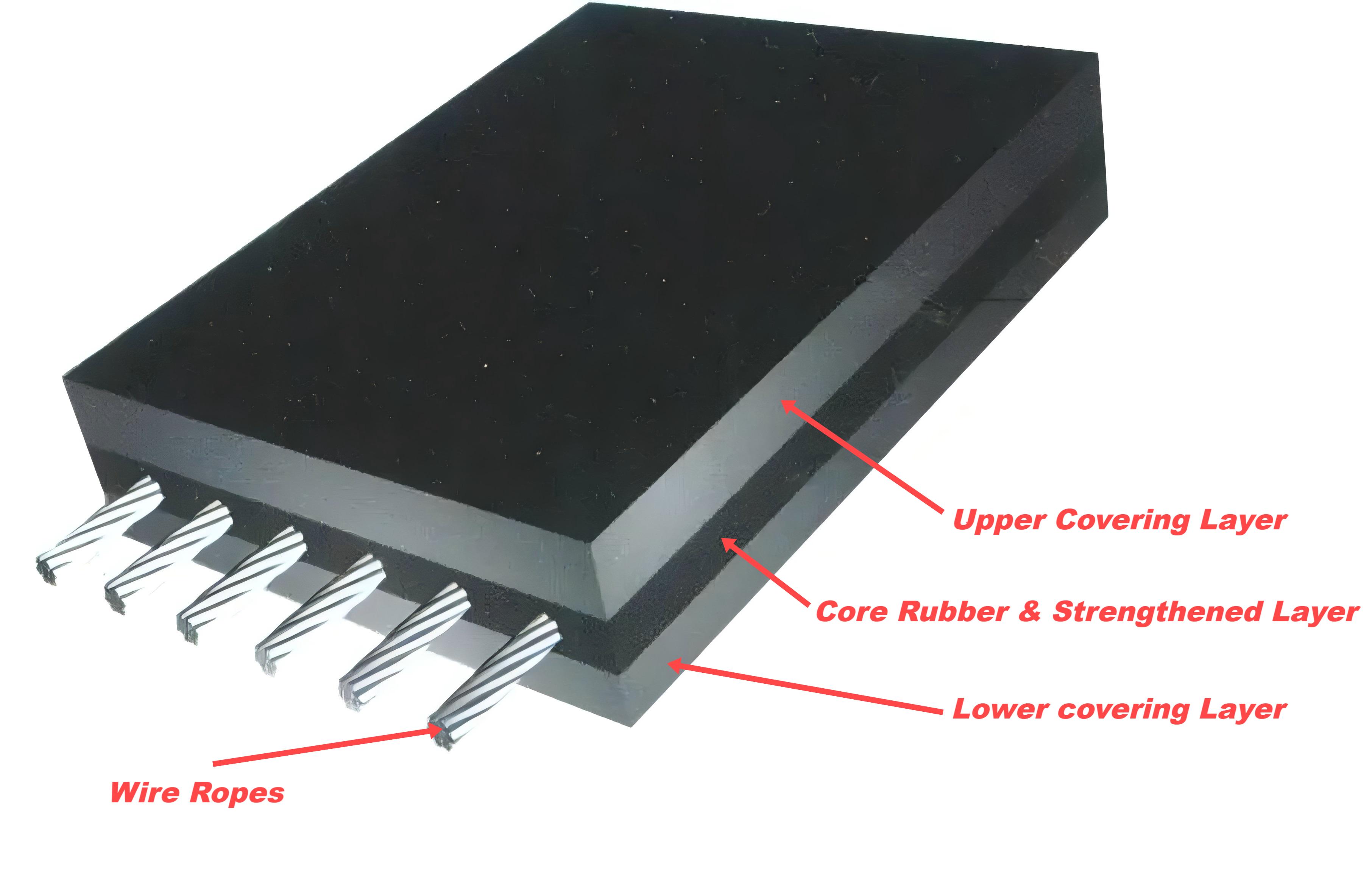

The anti- tear conveyor belt has highly extensible transverse steel cords or polyester cords evenly arranged in the top cover (or both top and bottom cover) of the steel cord carcass. The anti-tear layer is perpendicular to the running direction of belt. When the belt conveys hard and sharp materials, the anti-tear layer can stop it from being pierced. Even if the belt is pierced, the anti-tear layer can still prevent it from being torn.

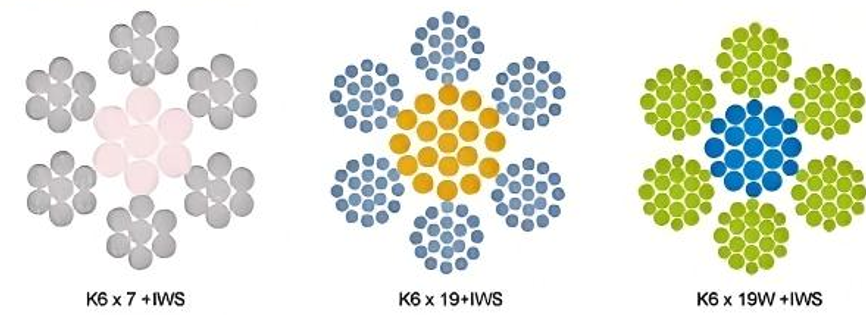

Steel cord composilion

|

|

Standard Specifications

| Strength grade | Tensile strength | Cord pitch | Cord diameter | breaking force(Min.) | cover thickness |

| (KN/m) | (mm) | (mm) | (KN) | (mm) | |

| ST-500 | 500 | 10 | 2.5 | 5.5 | 4 |

| ST-630 | 630 | 10 | 2.8 | 7 | 4 |

| ST-800 | 800 | 10 | 3 | 8.9 | 4 |

| ST-1000 | 1000 | 12 | 3.7 | 12.9 | 4 |

| ST-1250 | 1250 | 12 | 4.2 | 16.1 | 4 |

| ST-1400 | 1400 | 12 | 4.3 | 18 | 4 |

| ST-1600 | 1600 | 12 | 4.7 | 20.6 | 4 |

| ST-2000 | 2000 | 12 | 5.3 | 25.6 | 4 |

| ST-2250 | 2250 | 12 | 5.3 | 29 | 4 |

| ST-2500 | 2500 | 15 | 6.8 | 40 | 5 |

| ST-2800 | 2800 | 15 | 7 | 44.8 | 5 |

| ST-3150 | 3150 | 15 | 7.8 | 50.5 | 5.5 |

| ST-3500 | 3500 | 15 | 8.2 | 56 | 6 |

| ST-4000 | 4000 | 15 | 8.8 | 63.5 | 6.5 |

| ST-4500 | 4500 | 16 | 9.7 | 76.3 | 7 |

| ST-5000 | 5000 | 17 | 10.9 | 91 | 7.5 |

| ST-5400 | 5400 | 17 | 11.3 | 98.2 | 8 |

| ST-6300 | 6300 | 19.5 | 12.8 | 130.4 | 10 |

| ST-7000 | 7000 | 19.5 | 13.5 | 142.4 | 10 |

| ST-7500 | 7500 | 21 | 13.8 | 166.7 | 10 |

| ST-8000 | 8000 | 21 | 14 | 180.9 | 10 |

| ST-9000 | 9000 | 21 | 14.8 | 203.2 | 11 |

| ST-10000 | 10000 | 21 | 15.5 | 225 | 11 |

Note: Cover thickness, cord diameter, and cord pitch can be manufactured according to customer’s requirements.

Cover Properties

| Grade | Tensile strength(min.) | Elongation at break(min.) | Abrasion(max.) |

| Mpa | % | mm³ | |

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| L | 15 | 350 | 200 |

| Ka | 15 | 350 | 200 |

| Note: Ka for flame-resistant and anti-static belts in accordance with ISO340 and ISO284. | |||

The values will help to determine the appropriate cover compound for the application or for the materials carries. Reliable assessment of the behavior of the covers in service for wear and cut resistance cannot be determined from tensile strength, and abrasion values alone.

Anti-tear Steel Cord Conveyor Belt

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

Anti-tear Steel Cord Conveyor Belt

Contact Us

Classification

Keywords