Usage

It is suitable for conveying high temperature solid materials like sintering ore, coke, cement clinker, etc. which is used in metallurgical, cement, chemical industry and so on.

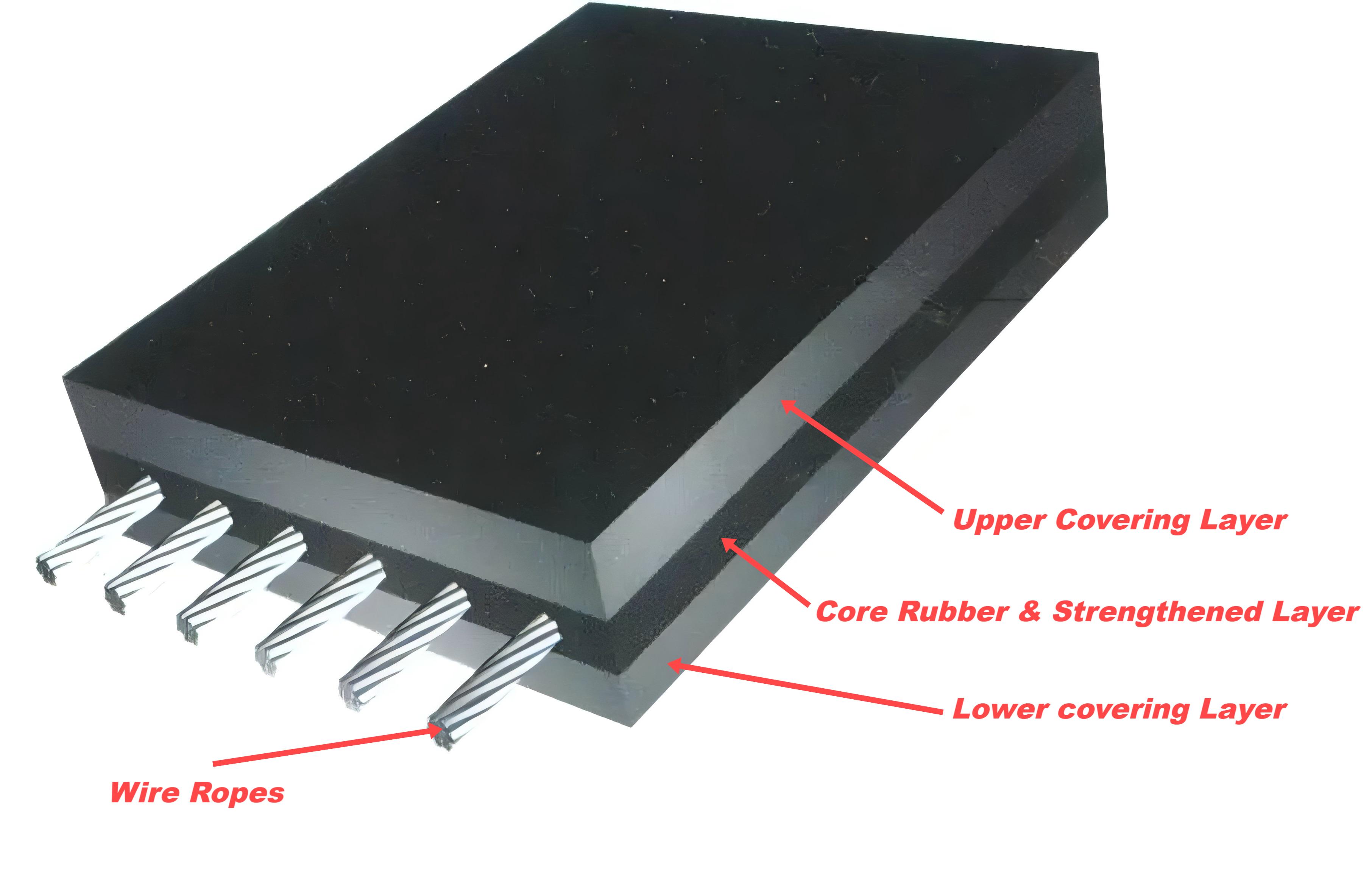

Characteristics

Developed new structure carcass materials will reduce the strength loss of heat aging during running, and thus will extend the working life.

The cover uses superior ethylene-propylene rubber or halogenate rubber which will enhance the high temperature resistant property of the rubber and reduce the loss of heat aging.

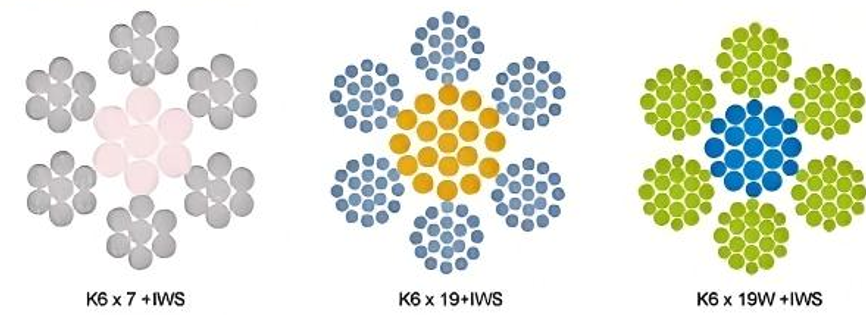

Steel cord composilion

|

|

Standard Specifications

| Strength grade | Tensile strength | Cord pitch | Cord diameter | breaking force(Min.) | cover thickness |

| (KN/m) | (mm) | (mm) | (KN) | (mm) | |

| ST-500 | 500 | 10 | 2.5 | 5.5 | 4 |

| ST-630 | 630 | 10 | 2.8 | 7 | 4 |

| ST-800 | 800 | 10 | 3 | 8.9 | 4 |

| ST-1000 | 1000 | 12 | 3.7 | 12.9 | 4 |

| ST-1250 | 1250 | 12 | 4.2 | 16.1 | 4 |

| ST-1400 | 1400 | 12 | 4.3 | 18 | 4 |

| ST-1600 | 1600 | 12 | 4.7 | 20.6 | 4 |

| ST-2000 | 2000 | 12 | 5.3 | 25.6 | 4 |

| ST-2250 | 2250 | 12 | 5.3 | 29 | 4 |

| ST-2500 | 2500 | 15 | 6.8 | 40 | 5 |

| ST-2800 | 2800 | 15 | 7 | 44.8 | 5 |

| ST-3150 | 3150 | 15 | 7.8 | 50.5 | 5.5 |

| ST-3500 | 3500 | 15 | 8.2 | 56 | 6 |

Note: Cover thickness, cord diameter, and cord pitch can be manufactured according to customer’s requirements.

Cover Properties

| Item | GB20021 Standard | Dongfeng Rubber Standard | |||||

| T1 | T2 | T3 | T4 | DFHR150 | DFHR180 | ||

| Test temperature | |||||||

| ≤100°℃ | ≤125°℃ | ≤150°℃ | ≤175°℃ | ≤150°℃ | ≤180°℃ | ||

| Permitted change range | |||||||

| Hardness | Difference before and after aging | +20 | +20 | ±20 | ±20 | ±10 | ±10 |

| Maximum after aging | 85 | 85 | 85 | 85 | 75 | 75 | |

| Tensile strength | Change rate of property % | -25 | -30 | -40 | -40 | ±15 | ±25 |

| Minimum value after aging | 12 | 10 | 5 | 5 | 10 | 8 | |

| Elongation at break | Change rate after aging % | -50 | -50 | -55 | -55 | ±15 | ±15 |

| Minimum value after aging | 200 | 200 | 180 | 180 | 400 | 350 | |

Heat Resistant, High Temperature Resistant Steel Cord Conveyor Belt

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

Heat Resistant, High Temperature Resistant Steel Cord Conveyor Belt

Contact Us

Classification

Keywords